Multi-span film greenhouse

The multi-span film greenhouse is a type of multi-span greenhouse covered with plastic film. It is a highly cost-effective facility type in modern agriculture, featuring good light transmission, heat preservation and economy. With a simple structure, it is suitable for large-scale planting and seasonal production. By rationally designing the supporting systems (such as ventilation, heat preservation and irrigation), efficient cultivation of crops can be

achieved in different climate zones, and it is widely used in the large-scale planting of vegetables, flowers, fruits and other crops. It is one of the mainstream choices for the popularization of facility agriculture.

I. Classification and Applicable Scenarios

According to functional and structural differences, multi-span film greenhouses can be classified into the following types:

1、Simple multi-span film greenhouse

Features: Simple structure, no complex temperature control equipment, only equipped with basic ventilation and shading systems.

Applicable scenarios: Spring and autumn planting (such as vegetable seedling raising, strawberries, leafy vegetables), short-term flower cultivation.

2. High-end multi-span film greenhouse

Features: Added fan wet curtain cooling, inner insulation curtain, and an automated control system (temperature and humidity monitoring, automatic start and stop of shading/ventilation).

Applicable scenarios: Year-round planting (such as tropical fruits and high-value-added flowers), factory seedling cultivation.

3. Serrated multi-span film greenhouse

Features: The roof is serrated, providing excellent natural ventilation without the need for additional fans (utilizing the thermal pressure effect to accelerate air circulation).

Applicable scenarios: High-temperature and high-humidity areas, suitable for crops with high ventilation requirements (such as orchids and edible fungi).

Ii. Application Scenarios

Vegetable cultivation

For the winter and spring harvests of solanaceous fruits (tomatoes, peppers) and melons (cucumbers, melons), the growth period is extended and they can be brought to market earlier.

In summer, plant heat-resistant leafy vegetables (such as lettuce and water spinach) under shade to avoid the high-temperature obstacles in the open air.

Flower production

Large-scale cultivation of cut flowers (roses, lilies) and potted flowers (Phalaenopsis, succulents) to control the flowering period and quality.

Fruit cultivation

Strawberry facilitated cultivation (with heating to achieve cross-year fruiting) and grape rain-sheltered cultivation (to reduce diseases and increase sugar content).

Seedling cultivation and scientific research

Vegetable and flower seedling factories, providing a stable environment to increase the emergence rate; Agricultural scientific research experiments (variety comparison, water and fertilizer management research).

Iii. Supporting Systems

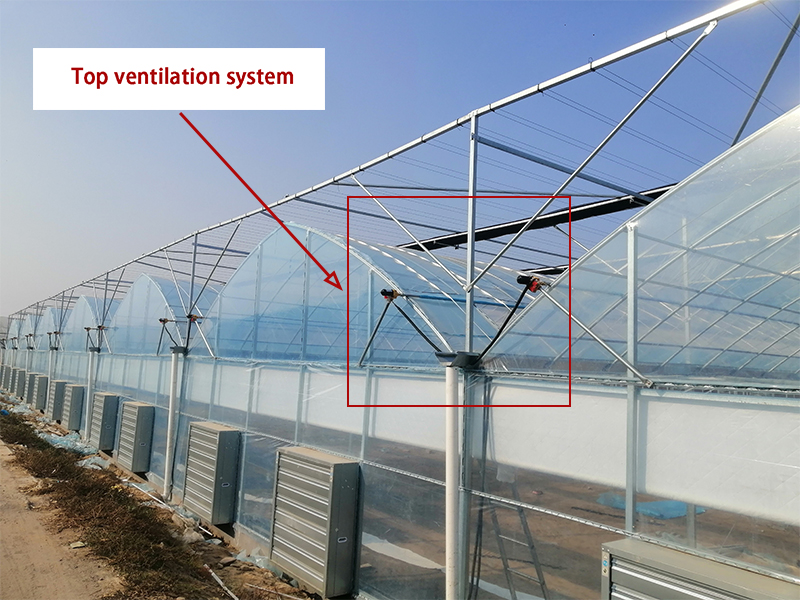

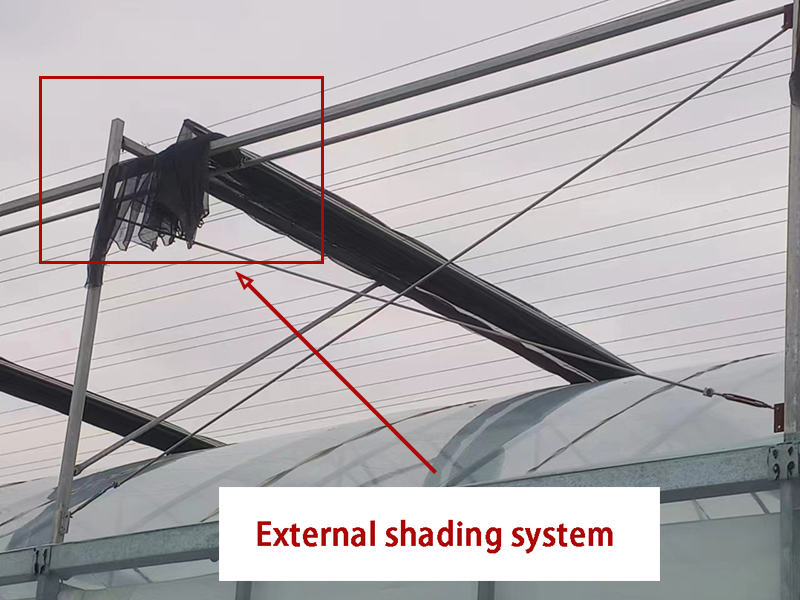

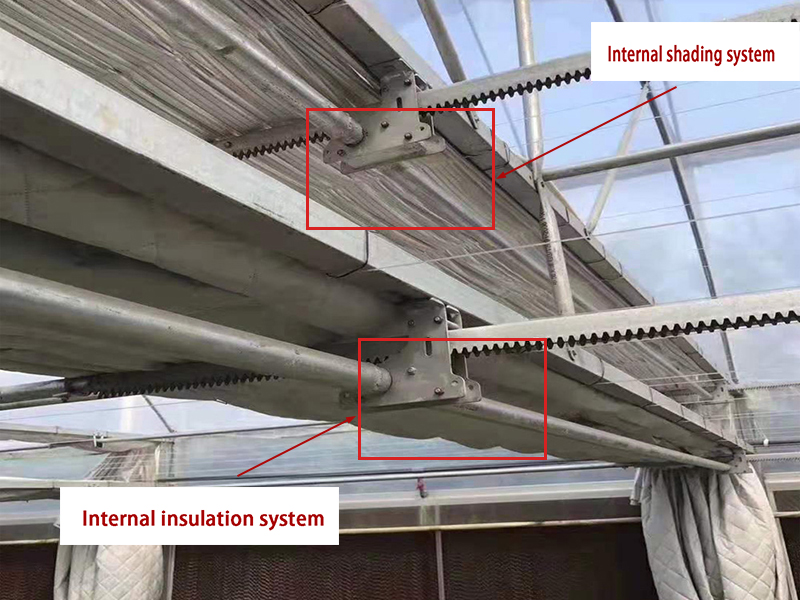

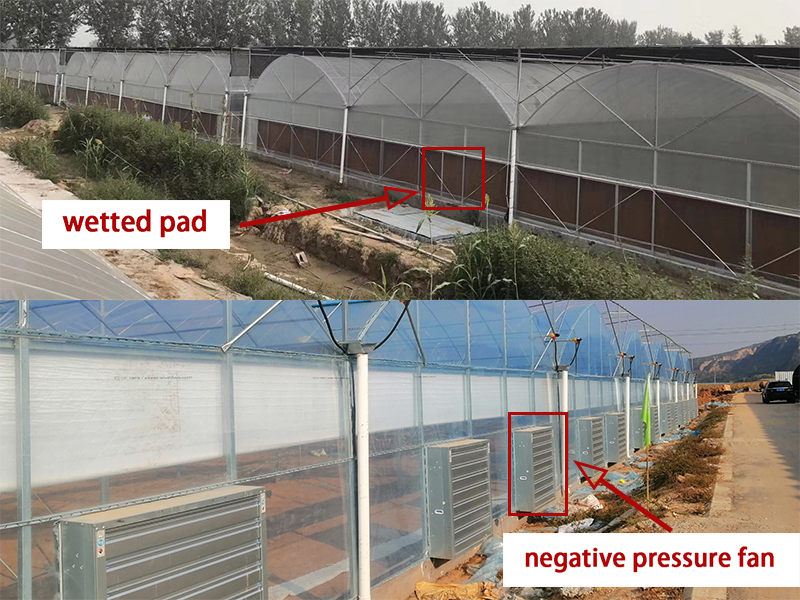

Supporting systems: ventilation system (top ventilation openings, side window ventilation), shading system (external shading net), insulation system (internal insulation curtain), irrigation system (drip irrigation, sprinkler irrigation), temperature control system (fan wet curtain), etc.

The main structure is composed of multiple single greenhouses connected by gutters (water channels connected to the roof). The span (transverse width) and bays (longitudinal spacing) can be designed according to requirements. The common span is 8 meters, and the distance between two arches is 4 meters. Main material: It adopts an all-steel frame structure form; The main arch frame, purlins, columns, etc. are all made of hot-dip galvanized rectangular steel frames to ensure the high overall structural strength of the greenhouse and prevent deformation. The main structure is composed of multiple single greenhouses connected by gutters (water channels connected to the roof). The span (transverse width) and bays (longitudinal spacing) can be designed according to requirements. The common span is 8 meters, and the distance between two arches is 4 meters. Main material: It adopts an all-steel frame structure form; The main arch frame, purlins, columns, etc. are all made of hot-dip galvanized rectangular steel frames to ensure the high overall structural strength of the greenhouse and prevent deformation. |

The main function of the ventilation system at the top of the greenhouse is to cool down, dehumidify, exchange air and regulate the airflow. It can achieve one-click opening and closing of multiple Windows through an intelligent system. |

The function of external shading 1. Blocking strong light: It can block strong light and provide suitable lighting conditions for greenhouses. 2. Heat insulation and cooling: It can effectively reflect and absorb solar radiation heat, preventing heat from entering the greenhouse interior. 3. Prolonging the service life of facilities: External shading can reduce the direct exposure of sunlight to the greenhouse film or other covering materials, slow down the aging speed of the materials, and thus extend the service life of the greenhouse facilities. 4. Energy conservation: The use of external shading can reduce the frequency and duration of operation of ventilation and cooling equipment as well as air conditioners and other refrigeration devices. |

The function of internal shading is: 1. To regulate light; 2. Lower the temperature; 3. Regulate the humidity in the greenhouse; 4. Protect crops. Greenhouse insulation is achieved through physical barriers, heat storage, artificial intervention and other means to create a stable warm and hot environment. Its core value lies in breaking through climate limitations, ensuring crop growth and improving production efficiency. |

The greenhouse fan and wet curtain system is the core equipment for regulating the greenhouse environment in summer. Through the synergistic effect of mechanical ventilation and water vapor evaporation cooling, it achieves temperature reduction, humidity regulation and air circulation inside the greenhouse, creating a suitable growth environment for crops. |

Greenhouse planting and harvesting facilities include: soilless cultivation planting troughs, seedbeds, vine drop hooks, picking cart series, etc. |

Integrated water and fertilizer management is an agricultural technology that organically combines irrigation and fertilization. It supplies water and fertilizer through a controllable pipeline system, and after the water and fertilizer are mixed, they are evenly and accurately delivered to the soil around the roots of crops. |

The intelligent greenhouse control system is a comprehensive management system that precisely monitors and intelligently regulates the greenhouse environment (such as temperature, humidity, light, carbon dioxide concentration, etc.) and production processes (such as irrigation, fertilization, ventilation, etc.). Its function is to optimize the growth conditions of crops, enhance production efficiency, reduce labor costs, increase yield and quality, and it is suitable for modern facility agriculture. |